Universities and colleges need more beds delivered with certainty on time and on budget. If you work with student residences you already know the constraints. Demand keeps rising, sites are tight, semesters do not move, and the student experience depends on acoustics, durability, and comfort. This article moves straight to solutions.

Precast for student housing, built around exterior insulated wall assemblies with interior concrete, can improve schedule, cost certainty, long term operations, and sustainability while giving students quiet, modern places to live and learn across on campus and off campus settings.

Why exterior insulated precast works for student residences

At the heart of prefabrication for student housing is the envelope strategy.

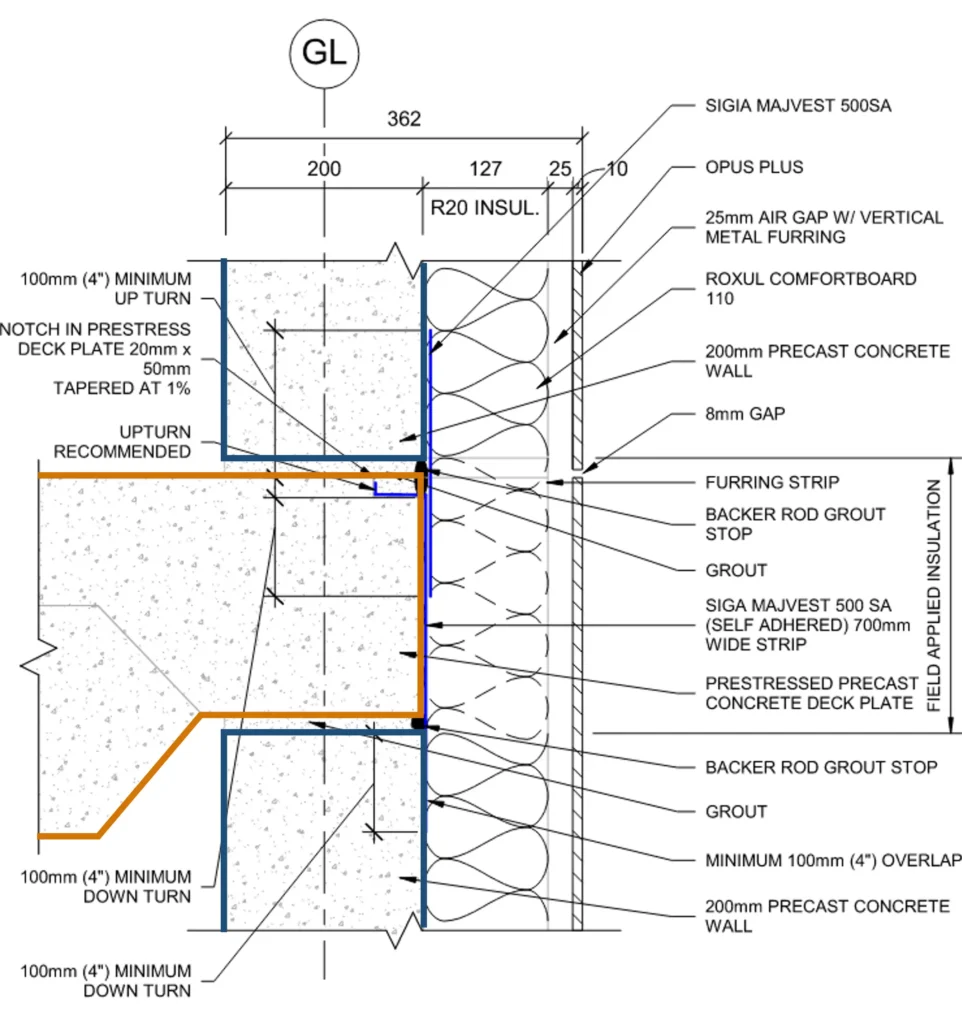

Placing continuous insulation on the exterior of the structure keeps interior concrete warm and dry, which supports energy performance, durability, and occupant comfort. Interior concrete walls resist dents and everyday wear, unlike drywall. That matters in a dorm and co-living environment with high turnover and high traffic.

The mass of concrete smooths temperature swings so rooms feel more stable across the day. When panels arrive factory finished and sized to the model, site work is faster and more predictable and air barrier continuity becomes easier to detail.

For the technical deep dive, download the Exterior Insulation & Concrete Walls whitepaper from our resources page. It explains the building science behind exterior insulation paired with interior concrete.

Exterior Insulation & Concrete Walls Whitepaper

Speed, certainty, and less disruption on campus

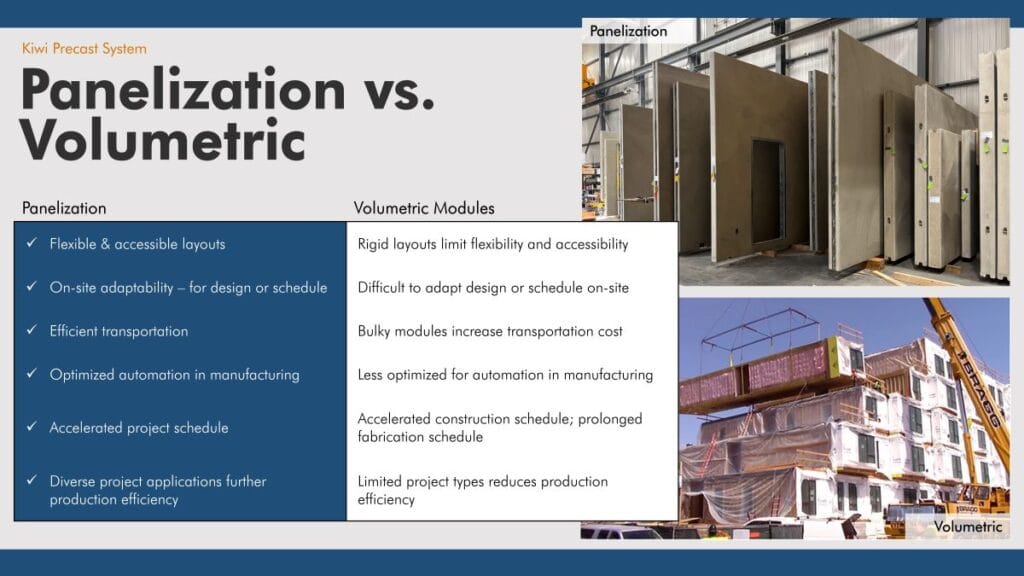

Construction windows around exams, move in week, and graduation are tight. A panelized approach with prefabricated modular construction compresses enclosure time, reduces weather risk, and cuts the number of noisy trades on site. Fewer deliveries and faster crane days mean less downtime for campus life. Factory planning also supports more reliable pricing earlier in design, which helps trustees and finance teams make decisions with confidence.

Behind that speed is manufacturing discipline. Modern precast concrete relies on repeatable formwork, controlled curing, and quality checks that are difficult to match outdoors. This kind of precast manufacturing supports reliable tolerances, clean interfaces at windows and balconies, and consistent air barrier detailing that can translate into real operational savings for a single building operator.

Durability that fits student living

Student housing is different from typical apartments. Move ins are concentrated, furniture comes and goes, and walls take a beating. Concrete interior walls are robust, easy to clean, and stand up to the cycles of student living and co-living. They support quieter rooms with higher sound transmission ratings than lightweight partitions. The result is fewer work orders between terms, less patching and repainting over the life of the building, and interiors that still look good on campus tours five and ten years later.

For universities that think in generations, this approach supports 100 plus year buildings. Long service life protects the reputation of the institution and stabilizes student experience. Modern residence halls often include communal kitchens, lounges, and dedicated study rooms. Precast floors and walls provide the spans and fire ratings those spaces need, along with excellent vibration performance for quiet study.

Performance that lowers energy and carbon

Exterior insulated mass walls are a proven path to lower energy intensity. They reduce thermal bridging, simplify airtightness, and make high performance targets more achievable. Many institutions are pursuing Net-Zero Buildings and even PassiveHouse Construction for student residences. Precast with exterior insulation supports those goals by cutting heating and cooling loads, which allows design teams to right size equipment and reduce mechanical complexity. That helps with long term operational savings on energy cost and maintenance.

Rooftops and facades can also be designed with solar power in mind. A stiff structure and repeatable roof details make photovoltaic layout and solar installation more straightforward, which is valuable for campuses with decarbonization roadmaps.

Related reading that illustrates the energy logic of exterior insulated mass walls: Energy Efficient Affordable Housing.

Flexibility beyond modular boxes

Modular student housing is often mistaken for a one size fits all approach. In reality, today’s modular precast supports varied unit mixes and amenity layouts. Panelized solutions let you tune window modules for daylight and privacy, create double loaded or single loaded corridors, and carve out suites that are fully accessible. You can keep a consistent structural and envelope logic while changing interior planning to match on campus and off campus program needs for dorm floors, graduate apartments, or family units. That flexibility helps teams deliver energy efficient student housing that does not feel generic.

Procurement that reduces risk

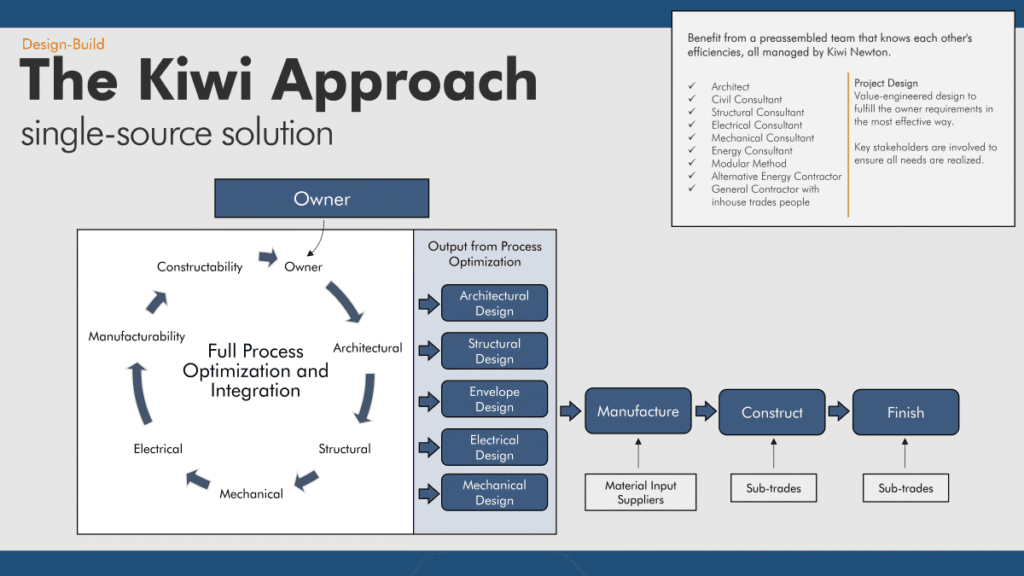

Schedule is critical, so procurement should lock in the supply chain early. Design-build residential or Progressive Design Build allows the design team and manufacturer to collaborate on details that drive cost and schedule.

Early decisions on panel grid, MEP routing, and envelope interfaces uncover risks before they hit the site. For public owners, this approach aligns with transparency and value for money while delivering the speed that student housing construction requires.

These projects are a form of multi-unit residential construction with campus specific needs such as RA suites, program floors, robust ground level finishes, and durable circulation areas.

Systemized precast in practice

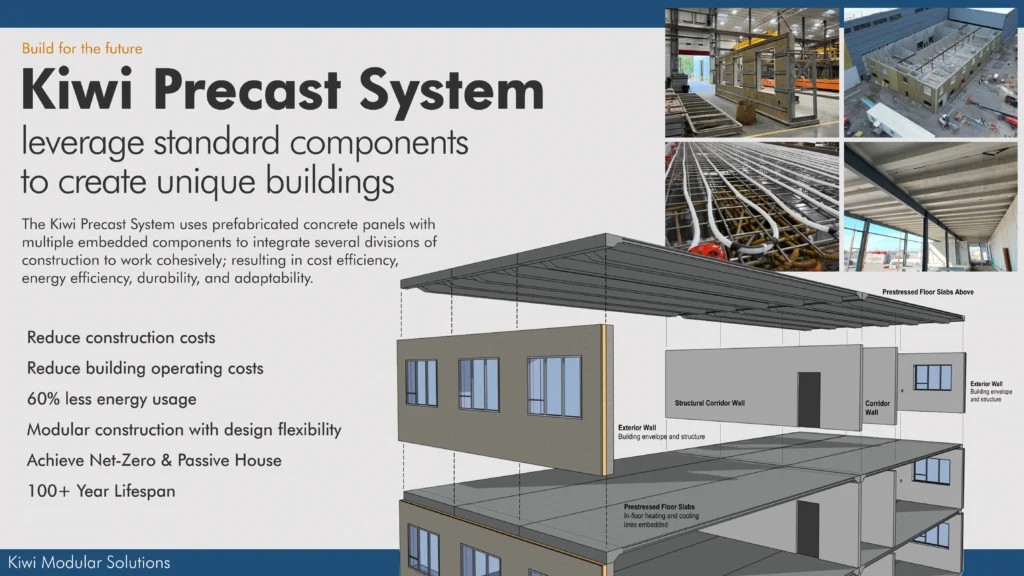

To make the ideas above more tangible, consider how a systemized approach brings structure, envelope, and services into one coordinated package. The Kiwi Precast System is an integrated precast system delivered within a broader precast building system.

Panels and connections are standardized around exterior insulation and interior concrete walls. Openings and sleeves are coordinated in the plant so the site team can set panels quickly and close the building earlier. Because it follows a total precast approach, structure and envelope work together, which shortens the critical path without sacrificing design quality.

This systemization also supports performance. Airtightness improves when the air barrier is planned around panel joints and factory cast openings. Thermal bridges are reduced when insulation is continuous on the exterior. These details are why the approach functions as energy efficient precast in day to day practice for student housing.

Cost, schedule, and operations in plain terms

- Construction cost. Prefabrication for student housing can reduce waste and rework through coordination and repeatability. Owners see a clearer cost picture earlier in design because the manufacturing scope is defined sooner.

- Construction schedule. Panel fabrication can run in parallel with foundations and erection is rapid, which means less disruption to campus. The site gets quiet sooner and there is less weather exposure.

- Operations. Durable interior finishes mean fewer repairs between terms. Smaller mechanical systems can lower maintenance hours. Better envelopes lower energy spend. Accessibility can be integrated into typical floors so that suites and common areas work for all students without compromises.

- Safety, noise, and comfort. Concrete walls contribute to fire resistance and acoustic separation. That matters in a dorm where sleep and study share a wall with social spaces. Quiet rooms and well ventilated common areas improve student living and support recruitment stories during campus tours.

Design-build checklist for student residences

Use this practical sequence to move a student housing project from idea to keys-in-hand with fewer surprises. It works for on campus and off campus sites, dorm style or apartment style, and supports energy efficient student housing targets.

1) Confirm programming and outcomes

- Program mix. Bed count, unit types, RA suites, accessible units, co-living clusters, graduate and family housing as required.

- Amenities. Communal kitchens, lounges, study rooms, wellness rooms, laundry, storage, bike parking, secure entry, mail and parcel areas.

- Operations profile. Turnover timing, maintenance windows, staffing model, custodial and security needs for student living.

- Performance targets. Energy use intensity, airtightness goals, acoustics for sleep and study, carbon goals such as Net-Zero Buildings.

- Financial frame. Capital budget ranges, target OPEX per bed, lifecycle horizon for a 100 plus year campus asset.

2) Choose a procurement path

- Design-Build Residential. Select a single team that carries design, pricing, schedule, and risk. Start early collaboration to integrate prefabrication. Learn more about design-build residential.

- Progressive Design-Build. Phase 1 preconstruction services to validate scope, cost, and schedule before converting to a final contract. Define deliverables, open-book pricing, and decision gates up front.

3) Engage your Design-Build partner early

- System briefing. Reach out to Kiwi Newton to learn more about the Kiwi Precast System and how prefabricated modular construction supports your program and calendar.

- Scope alignment. Confirm which elements are precast panels, interior concrete walls, floors, and stairs, plus interfaces with steel or in-situ concrete.

- Campus logistics. Discuss crane locations, delivery windows, noise limits, and exam periods to reduce downtime for campus.

4) Pre-design and Basis of Design

- Site and massing. Test fits that align panel grids with unit planning for dorms and apartments. Verify setbacks, fire access, and service yards.

- Envelope strategy. Commit to exterior insulation with warm interior concrete. Map continuity at balconies, parapets, slab edges, window heads, sills, and jambs.

- Structural rhythm. Choose bay sizes and floor-to-floor heights that optimize panel economy and livability.

- MEP approach. Right-size equipment using lower loads, plan ventilation and shafts, and coordinate cast-in sleeves and blockouts.

5) Validate cost and schedule early

- Concept pricing. Issue early drawings for takeoffs and panel counts. Request alternates that show cost and schedule options.

- Manufacturing and erection plan. Ask for milestones from mold setup to first panel pour to topping-out, with weather and exam contingencies.

- Campus continuity. Sequence enclosure so academic operations and residence life experience minimal disruption.

6) Schematic through Design Development

- Detail integration. Lock panel joints, anchors, window modules, and air-barrier transitions. Coordinate BIM content from the precast team.

- Performance checks. Thermal modeling at balconies and slab edges, acoustic goals for study rooms and sleeping areas, daylight for common rooms.

- Accessibility and safety. Barrier-free suites, clear wayfinding, egress, and fire ratings suited to student residences.

7) Preconstruction and approvals

- Authority engagement. Confirm code path, fire strategy, and inspections for a total precast approach.

- Stakeholder reviews. Residence life, facilities, IT, and security sign-offs on unit standards and common areas.

8) Manufacturing readiness

- Shop drawings. Approve panel drawings, connection details, and finish schedules. Align tolerances with field conditions.

- Mockups and QA/QC. Review a panel mockup for finish, joints, window installs, and flashing. Confirm inspection and test plans.

9) Site preparation and logistics

- Foundations and utilities. Prepare crane pads, laydown space, and delivery routes that fit the academic calendar.

- Safety and communication. Coordinate signage and campus notifications for move-in and exam periods.

10) Parallel fabrication and erection

- Weekly coordination. Track panel production, delivery, and install against milestones. Resolve field issues quickly.

- Early dry-in. Prioritize enclosure to protect interiors and accelerate MEP rough-ins.

11) Commissioning and verification

- Envelope testing. Perform air leakage testing and targeted thermal imaging of joints and penetrations.

- Systems commissioning. Verify HVAC, life safety, lighting controls, and metering. Train facilities staff on turnover workflows.

12) Handover and operations

- O&M package. Provide manuals, maintenance schedules, and turnover checklists tailored to high-traffic student living.

- Post-occupancy review. Check comfort, acoustics, and energy use at 6 and 12 months. Capture lessons for the next residence.

Talk with Kiwi Newton

Have a student housing program to advance this term or next year. Contact Kiwi Newton for a technical review of your goals and to learn more about the Kiwi Precast System and how prefabricated modular construction can support schedule, budget, and sustainability targets.